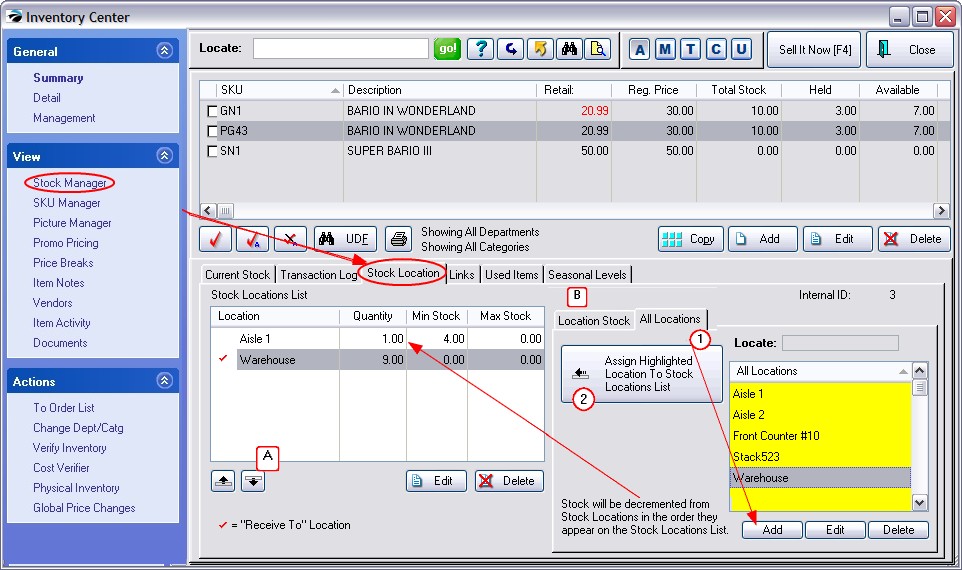

This is an optional feature of POSitive. It allows for tracking of stock counts by storage location. If the store has a warehouse or backroom as well as a showroom then stock counts can be controlled for each location.

(1) Define Location Names - On the Locations tab you add ALL buildings, shelves, rooms, walls, sections, etc. in as much detail as you wish.

(2) Assign Relevant Location(s) - Using the "Assign Highlighted Location...To List" button, select only those location names which apply to this inventory item.

The Locate field will help search and find a location in a long list.

TIP: the first location to be assigned to the item will become the default "Receive To" Location.

When inventory is received through purchase orders, the stock counts automatically update this "Receive To" location. To make a change, choose the Bin Stock tab to reassign which location will be the receiving location.

(A) If there is more than one location for the inventory item, sequence the Locations for removal of stock using the Up and Down Arrow buttons. By default, as items are sold, the stock count of the top most location will be decremented first.

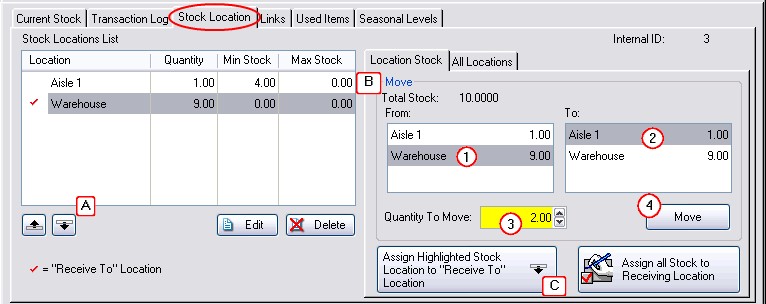

(B) When inventory needs to be moved from one location to another, select the Location Stock tab.

(1) FROM: Choose the location from which stock will be removed.

(2) TO: Choose the location to which stock will be moved.

(3) Enter the number of items to be moved.

(4) Choose the Move button.

(C) REORGANIZATION

If necessary, the "Receive To" location can be changed. Also, ALL stock counts for this inventory item can be moved back to the Receiving Location and then redistributed following the steps above.